In the construction industry, durability, cost-effectiveness, and performance are key priorities when it comes to concrete. One way to improve all three is by adding polypropylene fiber to concrete mixes. This small addition can make a big difference in strength, crack resistance, and long-term performance.

If you’re in the business of construction materials or concrete products, understanding why more and more professionals are turning to polypropylene fiber can help you make better decisions for your projects or product lines.

What is Polypropylene Fiber?

Polypropylene fiber (often shortened to PP fiber) is a synthetic fiber made from polypropylene resin. It’s lightweight, chemically stable, and resistant to moisture, making it ideal for use in cement-based materials like concrete, mortar, and plaster.

These fibers are added directly into the concrete mix, dispersing evenly to form a three-dimensional network. This reinforcement helps control shrinkage cracks and adds toughness to the concrete. Depending on the application, PP fibers come in different lengths and types—such as monofilament, fibrillated, or macro fibers—to meet specific performance needs.

At Mikem, we manufacture high-quality polypropylene fibers designed specifically for concrete applications. Our fibers are engineered for consistent performance and easy mixing, whether you’re producing ready-mix concrete, precast components, or dry-mix mortar products.

What Are the Benefits of Using Polypropylene Fiber in Concrete?

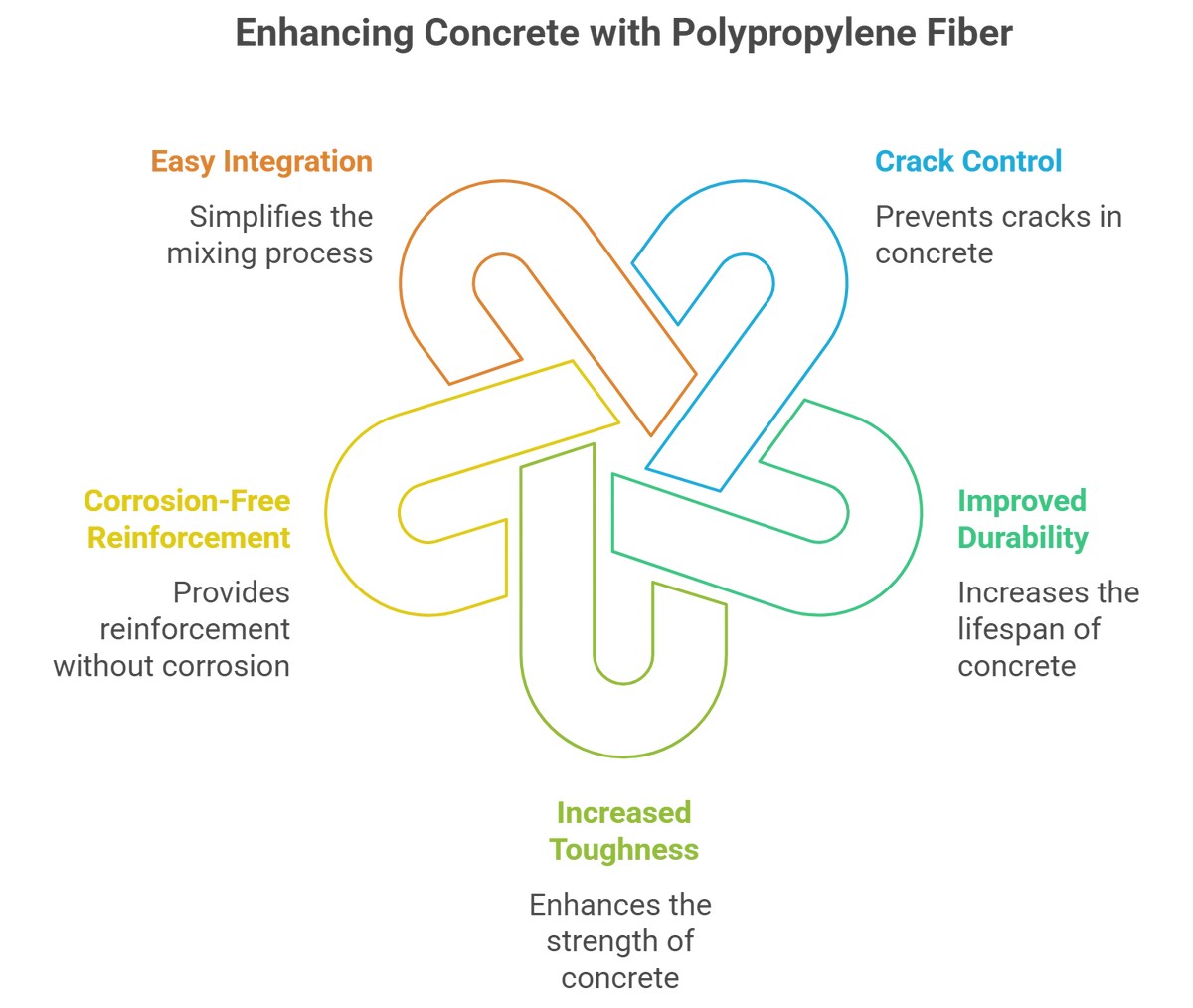

Adding polypropylene fiber to concrete brings a range of benefits that enhance both the fresh and hardened states of the material:

1. Crack Control

PP fibers are excellent at reducing plastic shrinkage cracks, which occur when concrete is fresh and water evaporates too quickly. The fibers create a web-like structure that holds the mix together, reducing the chances of early-age cracking.

2. Improved Durability

Concrete reinforced with polypropylene fiber is more resistant to impact, abrasion, and freeze-thaw cycles. This makes it especially valuable in harsh environments or where long-term performance is critical.

3. Increased Toughness

The presence of fibers in the mix gives concrete higher post-crack strength, meaning it can absorb more energy without breaking apart. This is particularly useful in industrial floors, pavements, and other high-load applications.

4. Corrosion-Free Reinforcement

Unlike steel mesh or rebar, polypropylene fibers won’t corrode. This makes them a reliable solution for extending the life of structures in moist or aggressive environments.

5. Easy Integration

Our polypropylene fibers are designed for easy dispersion in the mix, requiring no special equipment. They can be added at the batching plant or directly on-site, saving time and simplifying the construction process.

By choosing Mikem’s polypropylene fiber, contractors and manufacturers can achieve stronger, more durable concrete with less maintenance and reduced material waste over time. In addition, our carboxymethylcellulose (CMC) is commonly used in building materials to enhance performance and workability.

Key Applications of Polypropylene Fibers

Polypropylene fiber can be used in a wide range of concrete-based products. Here are some of the most common applications:

Industrial and Warehouse Floors

Enhances surface durability and reduces cracking under heavy loads.

Precast Concrete Elements

Improves handling strength and helps maintain shape during transport and installation.

Shotcrete and Tunnel Linings

Increases cohesion and reduces rebound, making it more efficient for sprayed applications.

Residential Driveways and Pavements

Reduces cracking and spalling in areas exposed to weather and traffic.

Mortar, Plaster, and Renders

Helps prevent shrinkage cracks and improves workability, especially in hot or windy conditions.

Why Choose Mikem Polypropylene Fiber

1. Excellent Crack Resistance

Mikem polypropylene fiber significantly reduces plastic shrinkage and early-age cracking. Its uniform dispersion forms a 3D reinforcement network that holds the concrete matrix together from the moment it’s mixed.

2. Enhanced Durability

Our fibers improve concrete’s toughness and resistance to impact, abrasion, and freeze-thaw cycles—extending the life of floors, pavements, and structural elements in tough environments. To learn more about how to protect concrete against freeze-thaw cycles, read How Does Ice Melt Damage Concrete?

3. Corrosion-Free and Chemically Stable

Unlike steel fibers, polypropylene does not rust or react with concrete additives. Mikem fibers are chemically inert, ensuring long-term stability even in aggressive environments such as coastal or industrial areas.

4. Easy to Use and Mix

Mikem fibers are engineered for smooth dispersion with no clumping or floating. They’re compatible with both site-mixed and factory-produced concrete and require no special tools or handling, saving time and labor on every project.

5. Versatile Applications

From precast and ready-mix to shotcrete and dry-mix mortar, Mikem polypropylene fibers are suitable for a wide range of applications in residential, commercial, and industrial construction.

What Can You Get From Mikem

1. Focused Expertise

At Mikem, we specialize in manufacturing construction additives, with a strong focus on fiber reinforcement technology. Our technical know-how ensures that every batch meets consistent quality standards.

2. Custom Solutions

We work closely with our partners to provide customized fiber lengths, dosages, and packaging based on specific project or product requirements. Flexibility is part of our service.

3. Global Supply, Local Support

With an established export network and reliable logistics, we serve clients across regions. Whether you’re sourcing for local production or global projects, Mikem ensures on-time delivery and responsive communication.

4. Consistent Quality Assurance

Our products are produced under strict quality control protocols, backed by detailed technical data and testing. When you choose Mikem, you’re choosing performance you can rely on.

5. Long-Term Partnerships

We don’t just sell fibers—we build relationships. Mikem supports every client with ongoing technical guidance, product updates, and industry insight to help you grow your business with confidence.

Build Stronger with Mikem

If you’re looking for a polypropylene fiber you can trust for quality, consistency, and long-term support, Mikem is your reliable partner. Join the many construction professionals and manufacturers who are already seeing the difference.

Contact us today to learn more or request a sample.