Differences Between Plasticizer and Superplasticizer: A Complete Guide for Beginners

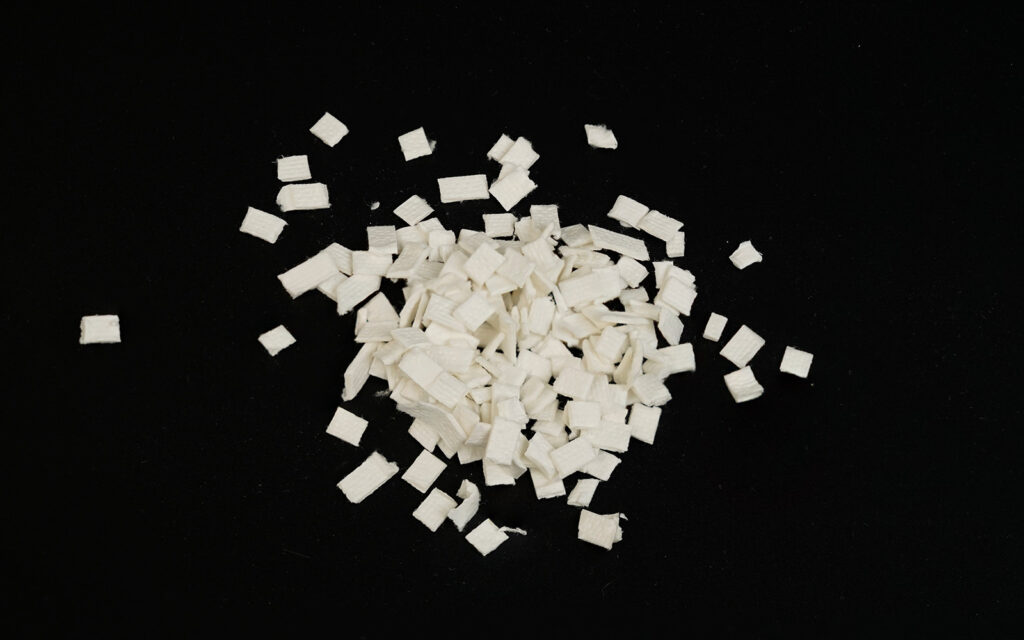

Understand the differences between plasticizers and superplasticizers, how they improve concrete strength, durability, flowability, and which one is best for modern construction.